How we do it

01/ Keeping your engineering in motion

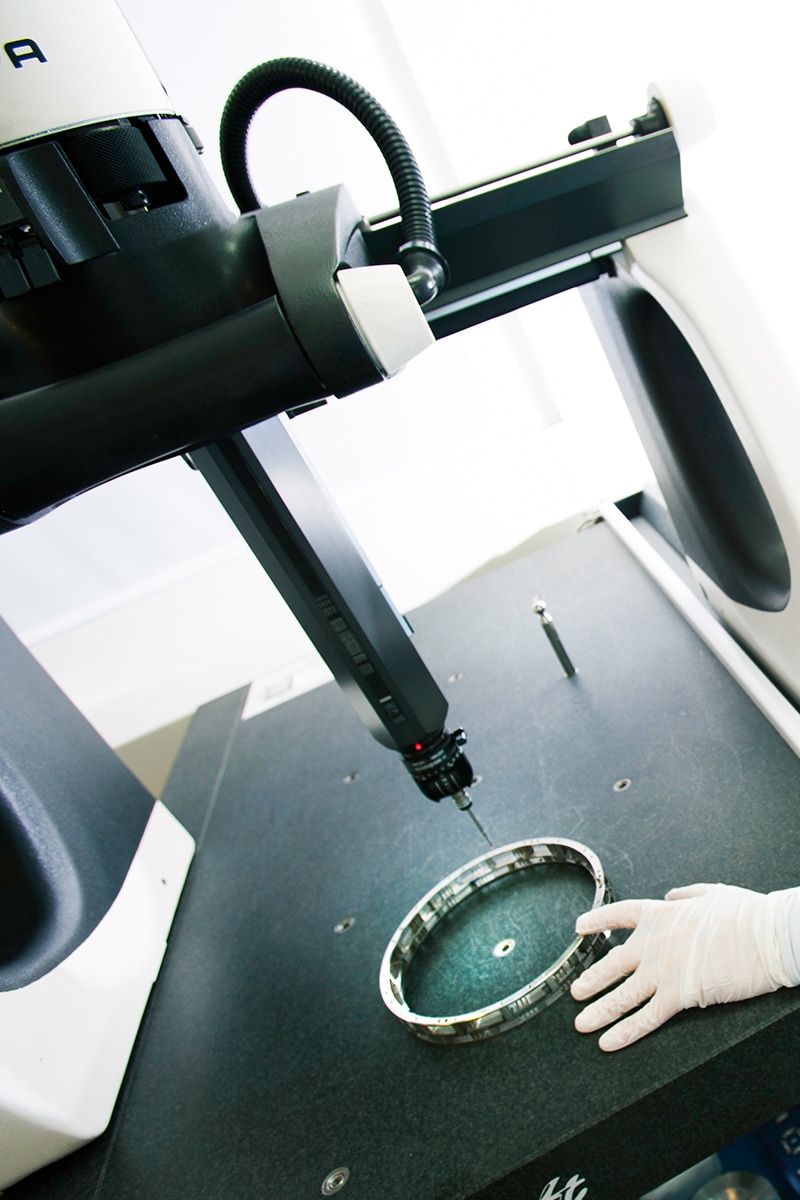

We’re experts on call. We solve problems when they crop up, through analysis, testing and solution development. We have the capacity to take on your challenge and rapidly deliver a solution – sometimes within days or weeks from first contact to reporting.

We have on-site capability to test while active, minimising downtime. We’re also there in a crisis, and the first port of call to support in major incidents, or as expert witness.

02/ Helping you to avoid failure

We carry out replication in software, physically built models, and custom test rigs; identifying the signals that herald failure, and offer solutions to improve performance, delivering proactive engineering design and maintenance to support uptime, and extend asset lifecycles.

Avoid the costs, disruption and dangers of premature mechanical, component and whole-system failure.

03/ World-leading engineers at the heart of your challenges

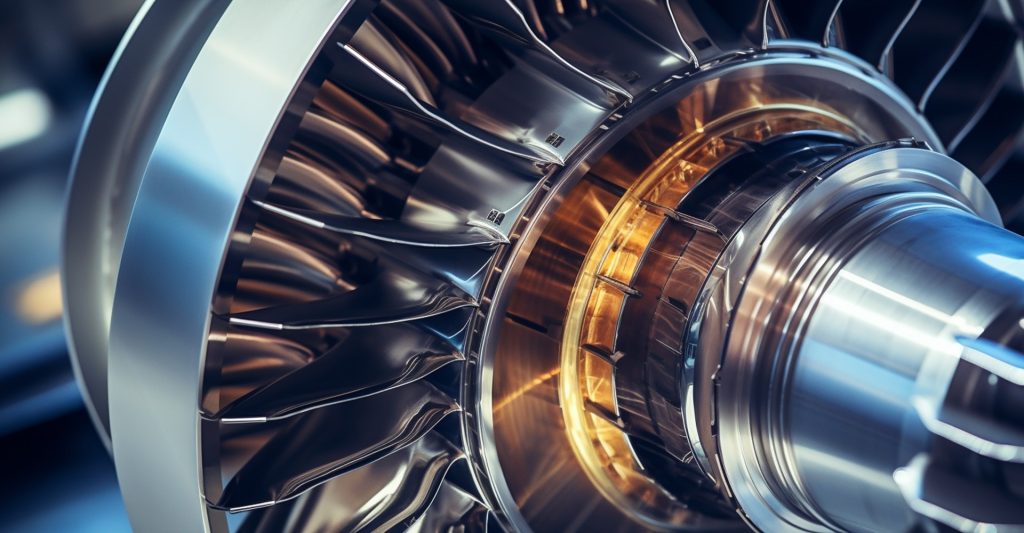

From precision vehicle mechanics and major urban infrastructure, to energy transition technologies and large commercial enterprises that cover multiple sites.

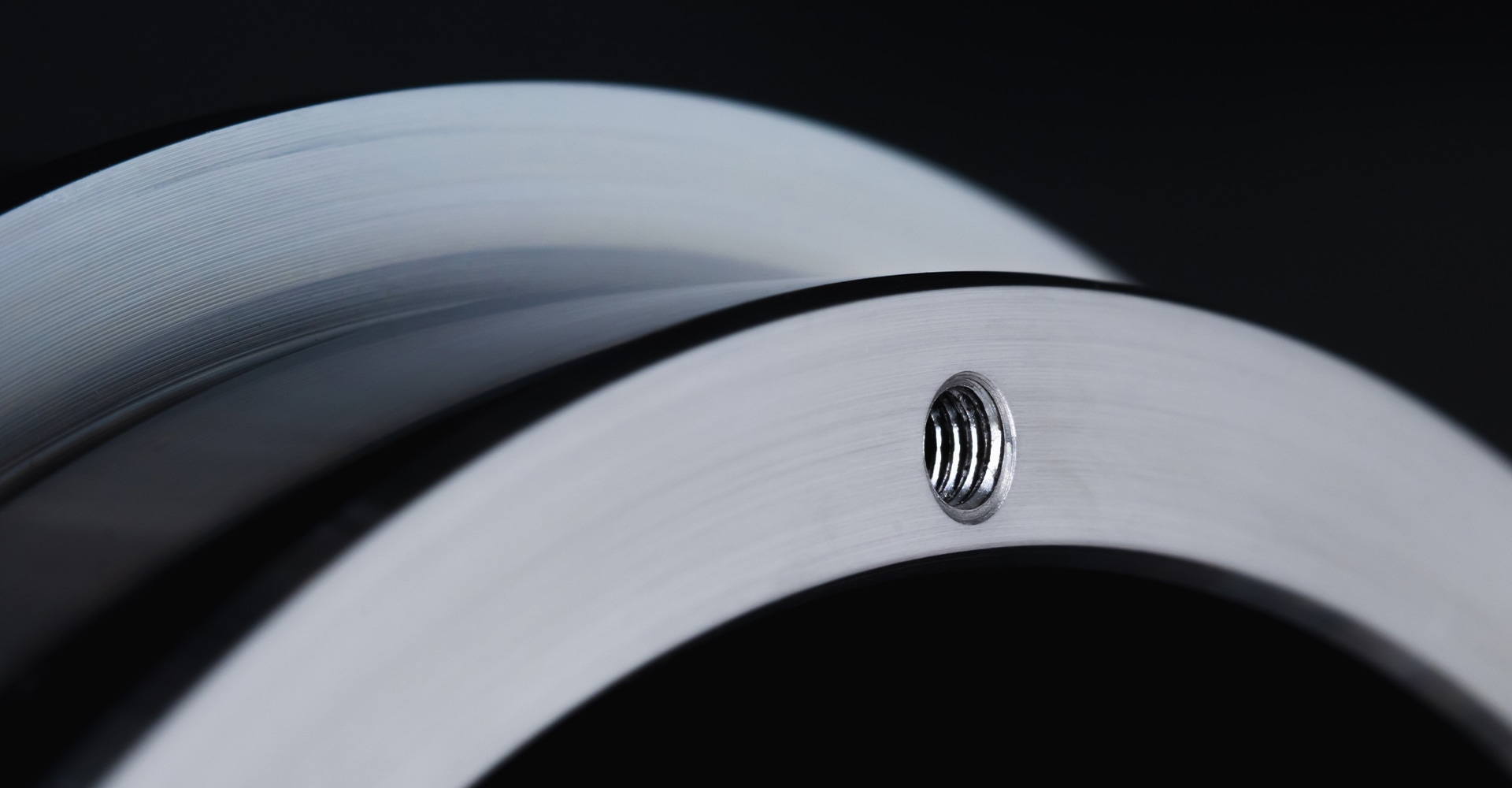

Our flexible team supports product and whole-systems development, with unique expertise in materials, component performance, mechanisms and specialist alloys. You can be confident that the solutions our people deliver, represent surface engineering and tribology at its best.

We’re experts on call. We solve problems when they crop up, through analysis, testing and solution development. We have the capacity to take on your challenge and rapidly deliver a solution – sometimes within days or weeks from first contact to reporting.

We have on-site capability to test while active, minimising downtime. We’re also there in a crisis, and the first port of call to support in major incidents, or as expert witness.

We carry out replication in software, physically built models, and custom test rigs; identifying the signals that herald failure, and offer solutions to improve performance, delivering proactive engineering design and maintenance to support uptime, and extend asset lifecycles.

Avoid the costs, disruption and dangers of premature mechanical, component and whole-system failure.

From precision vehicle mechanics and major urban infrastructure, to energy transition technologies and large commercial enterprises that cover multiple sites.

Our flexible team supports product and whole-systems development, with unique expertise in materials, component performance, mechanisms and specialist alloys. You can be confident that the solutions our people deliver, represent surface engineering and tribology at its best.